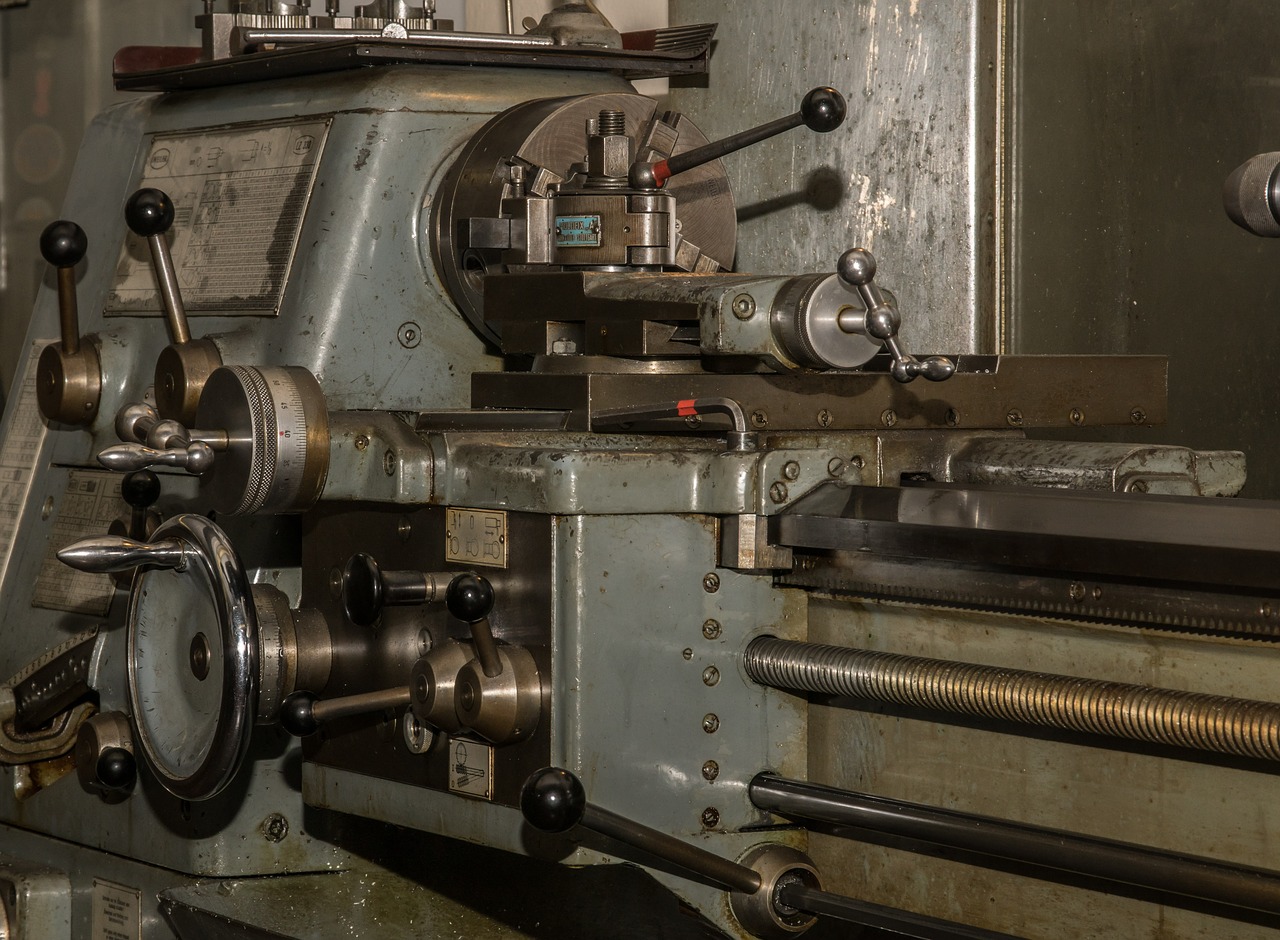

Basic Lathe Chucks Information You Need to Take Note Of

A chuck is a significant device on a lathe that used to hold and spin a workpiece during turning. It is held firm and rigid by a large, heavy, high-pressure, stiff steel lining that cannot be conveniently mounted in the middle. The latest technology achieves the precise alignment of the chuck on a lathe. This is useful for pieces with a circular cross-section, which has a small round rod that can be held by a spindle.

Square Jaw

The square jaw chuck is the most economical type of rotary chuck, whereby each cheekbone works independently of each other with different screws. Four chucks with independent molar clamp irregularly shaped materials such as wood, metal, wood chips, or other irregular materials. The jaws are not reversible and can only be adjusted by opening and closing the jaw with the keys simultaneously. The four-cheek combination feed can be combined with a quadruple feed, a double feed, or even a four-cheek feed. It is not as precise as the quadruple chuck, and you need two sets from the outside.

Jacobs Chuck

Jacobs Chuck

The Jacobs chuck is a common type of chuck that works with a long, precise handle, which is designed for use as a drill or round drill. It is generally used to drill into the tailstock of a lathe, but some special models are equipped with threaded spindles that hold small round bars in place. These chucks are ideal for square, rectangular or irregular parts that do not require regular …